The 2025 report by the Insurance Institute for Highway Safety (IIHS) warns that brake failures remain one of the leading causes of large truck crashes — despite decades of progress and new safety technologies.

Mechanical failures continue to play a major role in truck crashes across the United States. The IIHS first investigated this issue in the late 1980s, when researchers studying large truck crashes in Washington State found that trucks with mechanical defects were twice as likely to be involved in collisions as those in proper working condition.

The most common issue was brake failure, found in 56% of tractor-trailers involved in crashes. Steering equipment defects followed, appearing in 21% of cases.

Three decades later, a similar IIHS study conducted in North Carolina between 2010 and 2012 revealed that steering defects had become rare — but brakes remained a critical hazard. Faulty brakes were identified in 42% of crash-involved trucks, and those with defects severe enough to warrant removal from service had three times the crash risk. Overall, the presence of any mechanical defect was linked to a 200% increase in crash risk.

Nationwide data from the Large Truck Crash Causation Study (2001–2003) reinforced these findings: 55% of inspected trucks had at least one mechanical violation, and nearly 30% had a condition serious enough to take them immediately out of service. The most frequent violations involved braking systems (36%) and lighting systems (19%).

Braking Systems: The Weak Point of Heavy Transport

Unlike passenger vehicles, heavy trucks require far longer stopping distances — and the gap widens dramatically on wet or icy roads. Any failure in the braking system, whether due to poor maintenance or improper adjustment, can have fatal results.

Since the late 1990s, all new heavy trucks have been required to include antilock braking systems (ABS), automatic brake adjusters, and visible adjustment indicators to prevent skidding and jackknifing during emergency stops. The IIHS estimates that ABS-equipped tractor-trailers have a 65% lower crash risk, thanks to improved driver control and shorter stopping distances.

Safety Technology: Slow but Promising Progress

While passenger cars have rapidly integrated advanced driver-assistance systems, the heavy truck industry has been slower to follow. Since 2019, all new large trucks must feature Electronic Stability Control (ESC) — a system designed to prevent rollovers and loss of control on curves or ramps. According to IIHS estimates, ESC could prevent or mitigate up to 31,000 truck crashes annually, including 20% of serious injury crashes and 11% of fatal ones.

Complementary technologies such as forward collision warning (FCW), automatic emergency braking (AEB), and lane departure warning systems (LDW) could together prevent or lessen the impact of over 107,000 police-reported truck crashes each year, according to the same study.

In 2021, IIHS researchers found that large trucks equipped with AEB and FCW systems reduced front-to-rear collisions by 41% and 44%, respectively. Even when crashes still occurred, the systems reduced vehicle speed by about half — dramatically lowering injury severity.

Recognizing these benefits, Congress in 2021 directed regulators to require AEB on all trucks weighing more than 26,000 pounds. Two years later, the National Highway Traffic Safety Administration (NHTSA) proposed extending this rule to all new vehicles over 10,000 pounds and broadening the ESC mandate as well.

The Hidden Danger of Underride Crashes

One of the most devastating — and often overlooked — types of truck crashes is the underride, where a smaller vehicle slides partially or fully underneath a truck or trailer. A 1997 IIHS study found that half of all fatal crashes involving large trucks and passenger vehicles included underride, with 57% occurring at the front of the truck and 22% at the rear.

A federal rule enacted in 1998 required stronger rear underride guards on new trailers, but many vehicle types were exempt. After years of advocacy, NHTSA finalized an upgraded standard in 2022 to align U.S. regulations with the stricter Canadian rule in place since 2007. However, IIHS research has shown that these guards still fail in certain side or offset collisions.

In response, IIHS created the TOUGHGUARD award, recognizing trailer manufacturers that go beyond federal standards. Nine North American companies — including the eight largest — now produce trailers with advanced rear guards that prevent underride even in partial-overlap impacts at speeds up to 35 mph (56 km/h).

Still, the U.S. lacks any requirement for front or side underride guards, despite their proven effectiveness in Europe, where they’ve been mandatory since 2003. IIHS estimates that a national side guard mandate could prevent 160 to 220 passenger deaths annually.

The Road Ahead: Technology, Regulation, and Maintenance

The 2025 IIHS report makes one thing clear: improving truck safety requires a three-part strategy — better technology, stronger regulation, and consistent fleet maintenance.

The data shows undeniable progress: steering defects have declined, stability control systems are saving lives, and automatic braking is gaining ground. Yet the most common killers remain unchanged — poorly adjusted brakes, lax inspections, and incomplete safety standards.

As the U.S. moves toward broader adoption of crash-prevention systems and stricter mechanical oversight, the central challenge remains the same as it was three decades ago: ensuring that every truck on the road is truly roadworthy. Because when a 30-ton vehicle fails to stop in time, even a small defect can lead to catastrophic consequences.

The best roadside attractions for truckers in the U.S.

America’s highways hide unique places that break up the routine, don’t hesitate to check out these roadside attractions along the way. The road is much

The trucker style: comfort, function, and identity

Truckers’ style is much more than workwear; it’s an identity. These are the most commonly worn garments among truckers. Truckers’ style is much more than

Chaos on Highway 61: Viral Wrong-Way Truck Video Reignites the CDL Debate

An 80-ton tractor-trailer traveling miles in the wrong direction on Missouri’s Highway 61 has reignited a nationwide debate over Commercial Driver’s License (CDL) standards, training

How technology affects driver retention

Friend or foe? 52% of drivers say technology directly influences their decision to stay with or leave a fleet. Fleet telematics company Platform Science published

Dalilah Law seeks to remove non-english speaking commercial drivers

President Donald Trump proposed the “Dalilah Law,” an initiative aimed at prohibiting undocumented immigrants from obtaining commercial driver’s licenses. On February 24, President Donald Trump

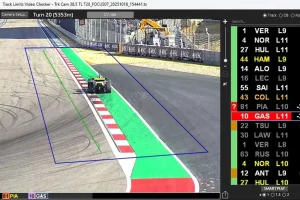

FORMULA 1 and the AI That Could Transform Transportation in the U.S.

The artificial intelligence system that Formula 1 implemented to monitor every car on every turn is opening the door to new applications in trucking, logistics,